COATING

Since 1926 Stoz GmbH has been handling the coating of components. Today, we offer you a wide range of possible coatings and paints at 13 coating plants.

By combining these with our pre-treatment process, we offer you top-quality protection for your components, regardless of whether they be steel, aluminium, magnesium, plastic, carbon or of any other construction. We offer both purely technical coatings and corrosion protection, and visually appealing surfaces such as high-gloss finishes, metallic effects and much more. With our certifications according to IATF 16949, including the ISO 9001 and ISO 9100 certifications, we can also offer you solutions for critical components intended for the automotive and aerospace sectors.

Coating systems:

Large throughput system

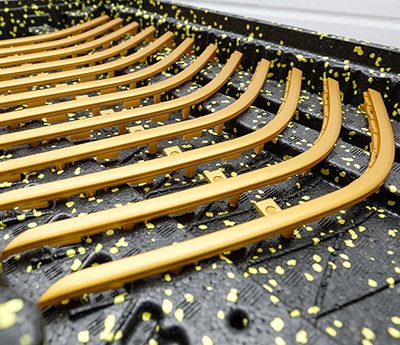

A plant for components of up to 2700 mm in length, coated to the highest quality. All-over, one- to three-layer coatings using ABB robots. Suitable for high-gloss coatings.

Medium throughput system

A plant for medium to large component geometries. Two ABB robots for one- and two-layer coatings. For technical and decorative coatings, as well as high-temperature coatings with baking temperatures above 200°C. Automatic turning stations also allow double-sided coating.

Small throughput system 1 + 2

Two fully automated coating systems equipped with ABB paint robots for components of up to one metre. Equipped with bottom conveyors and turning stations for double-sided coating.

Small parts throughput coating system

Automatic coating machine for radially symmetrical components in large quantities with automatic masking. Drying by infrared irradiation.

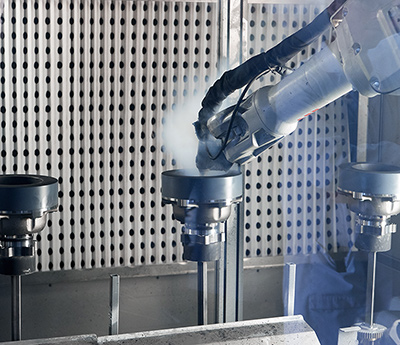

Portal robot system

Highly flexible semi-automated machine with ABB coating robot for components up to more than one metre. Drying of the components in the batch furnace.

All-round spraying machine

Sprimag all-round spraying machine for radially symmetrical components. Components dried by induction or in a batch furnace.

Hand-spraying equipment

Three hand-painting booths for components up to 3 metres in length. For small runs, sample parts or single and special components. Multilayer build-up with water- and solvent based coatings. Drying takes place in batch furnaces.

Spindle throughput system 1

A plant with an ABB coating robot and compressed air atomisation. Automatic robot-controlled cleaning of the components with CO2 snow or dry ice. For components up to 600 mm. Drying up to 180°C.

Spindle throughput systems 2 and 3

Two plants with ABB painting robots equipped with high-rotation atomisers and electrostatic technology for solvent-based coatings. For components up to 600 mm. Drying up to 180°C.

Coating systems

Water- and solvent-based coatings

Single- and multi-layer coating

Single- and multi-component coatings

Baked coatings

High-solid coatings

High-gloss coatings

Anti-corrosion coatings

Technical functional coatings

Fluoropolymer coatings

Soft-touch paint coatings

Special coatings on request